The “throttle body” is part of the intake system “fuel injection”

The fuel injection system (hereafter referred to as “injection”) uses a throttle body to mix gasoline and air to create an air-fuel mixture. Prior to the introduction of this mechanism, also known as the “intake system,” a “carburetor” was used.

However, as time went on, with stricter exhaust gas regulations and improved performance, motorcycles began to switch from simple carburetors to fuel injection, which was commonplace in automobiles.

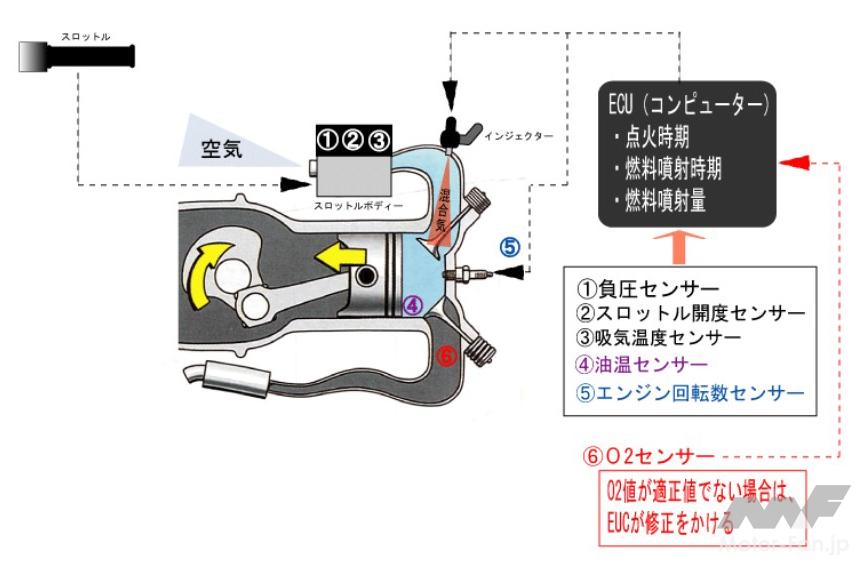

“Fuel injection” mechanism (image)

ADVERTISEMENT

ADVERTISEMENT

This electronically controlled throttle body is for the Suzuki DR-Z4S (SM) equipped with a water-cooled, 4-stroke, single-cylinder, DOHC, 4-valve, 398cc engine. It is a simple, cost-effective, wire-operated type that does not have an electric motor to operate and open/close the butterfly valve (throttle valve).

Generally, motorcycle injection systems are

1. “Negative pressure sensor” that measures negative pressure.

2. “Throttle opening sensor” that measures the opening of the throttle valve installed in the throttle body.

3. “Intake air temperature sensor” that measures the temperature of the intake air.

4. “Oil temperature sensor” that measures the temperature of the engine oil.

5. “Engine rotation sensor” that measures the engine rotation speed.

The ECU (Engine Control Unit, also known as a computer) collects data from sensors ① to ⑤, calculates the ideal mixture ratio (called the ideal air-fuel ratio, said to be the ratio at which complete combustion occurs when the air:fuel ratio is approximately 14.7:1), and commands the throttle body to produce the mixture.

In addition, the O2 sensor ⑥ installed in the exhaust pipe of the muffler measures the oxygen concentration of the exhaust gas. If the oxygen concentration is outside the specified value, the ECU sends a message to the throttle body to “produce a mixture that falls within the specified value.” *Note: This varies depending on the vehicle model.

The “throttle body,” which takes in air and creates an air-fuel mixture, generally has three sensors installed: 1) a vacuum sensor, 2) a throttle opening sensor, and 3) an intake air temperature sensor.

The carburetors used in the past had to be disassembled using tools to adjust for temperature, air pressure and tuning, the main jet replaced and the bike reassembled for real riding… this process was repeated over and over again. It was an “analog” system that required knowledge, experience and a sense of practice.

On the other hand, fuel injection is generally a “digital” system that allows you to access the ECU using a computer to change settings and rewrite maps, without getting your hands dirty.

Among high-end users, there are some who are so keen that they convert their fuel-injected vehicles to carburetor versions because they prefer the direct throttle feel of a carburetor over computer-controlled fuel injection.

The 12V Monkey 50 has been bored out to 88cc and is fitted with a Keihin PE24 carburetor. An air filter that combines intake efficiency and practicality has been installed on the intake port side.

ADVERTISEMENT

The carburetor draws air in by creating negative pressure when the piston descends. The jet needle (the needle in the middle), which is directly connected to the throttle, moves up and down to take in gasoline and create an air-fuel mixture.

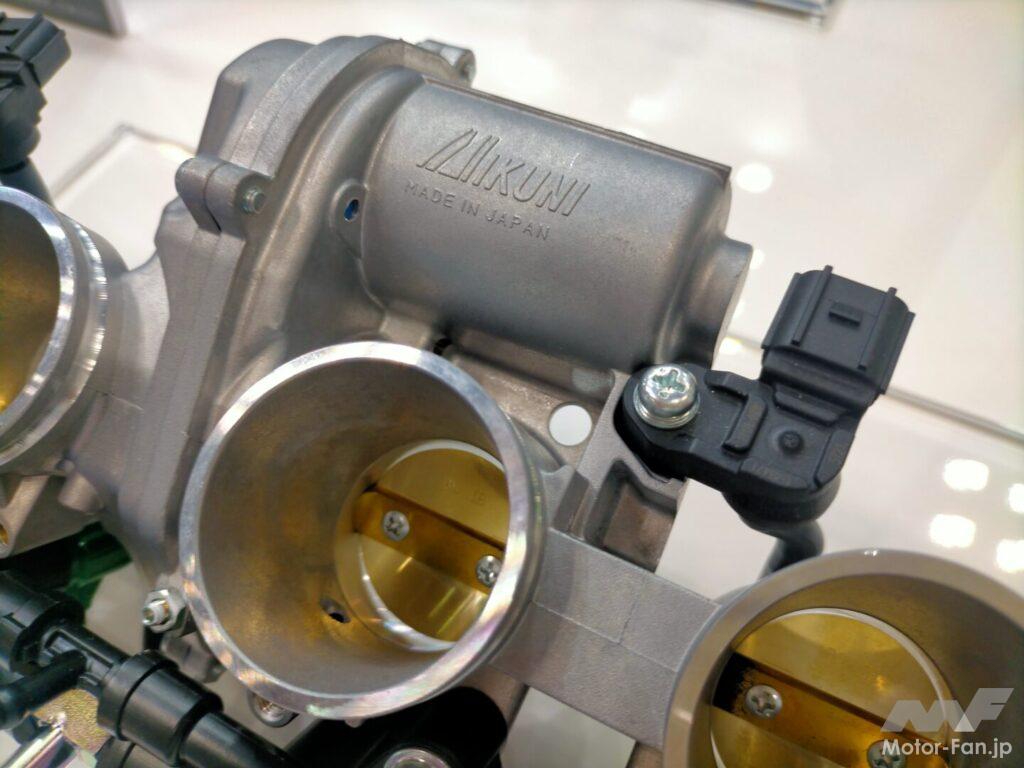

Electronically controlled throttle body for Kawasaki Z900

This electronically controlled throttle body is used as an original part for the Kawasaki Z900, which is equipped with a water-cooled, 4-stroke, inline 4-cylinder, DOHC, 4-valve, 948cc engine.

The center of the throttle body contains an electric motor that operates and opens and closes the butterfly valve (throttle valve/golden part) according to instructions from the ECU.

In order to operate the large diameter butterfly valves (throttle valves) equivalent to those of four cylinders, a larger electric motor is used than those used in other vehicles.

According to Mikuni, electric motor-operated systems are characterized by the fact that they are easier to achieve optimal air-fuel ratio performance than wire-operated systems (however, the difference in driving feel between the two is so great that an amateur would not be able to tell the difference). For this reason, ultra-high performance racing models that pursue performance tend to use high-performance electric motor-operated systems, even though they are expensive.

ADVERTISEMENT

ADVERTISEMENT

Kawasaki Z900

Electronically controlled throttle body for Kawasaki TERYX4 H2

This electronically controlled throttle body is used in the “TERYX4 H2” off-road four-wheeled machine, which is equipped with a water-cooled, four-stroke, inline four-cylinder, DOHC, four-valve, 999cc supercharged engine.

The upper right corner of the main unit houses an electric motor that operates and opens and closes the butterfly valves (throttle valves) for all four cylinders according to instructions from the ECU.

ADVERTISEMENT

Kawasaki TERYX4 H2

Electronically controlled throttle body for Suzuki DR-Z4S (SM)

Suzuki’s motard model, the DR-Z4S (SM), is equipped with a water-cooled, four-stroke, single-cylinder, DOHC, four-valve, 398cc engine. The photo shows the original electronically controlled throttle body that comes with the vehicle.

The electronically controlled throttle body used in this vehicle is a simple, cost-effective wire-operated type that does not have an electric motor to operate and open/close the butterfly valve (throttle valve).

ADVERTISEMENT

The DR-Z4S (SM) was exhibited at the Suzuki booth at the Japan Mobility Show 2025. The photo shows the model fitted with accessories.

Electronically controlled throttle body for water-cooled 4-stroke 90-degree V-twin engine

An electronically controlled throttle body developed for vehicles equipped with an Italian water-cooled, 4-stroke, 90-degree V-twin, DOHC, 4-valve, 890cc engine.

An electric motor for operating and opening/closing the butterfly valve (throttle valve) is installed on the cylinder 1 side (left side of the photo). The cylinder on the opposite side is linked and operated by a dedicated arm installed on the right side.

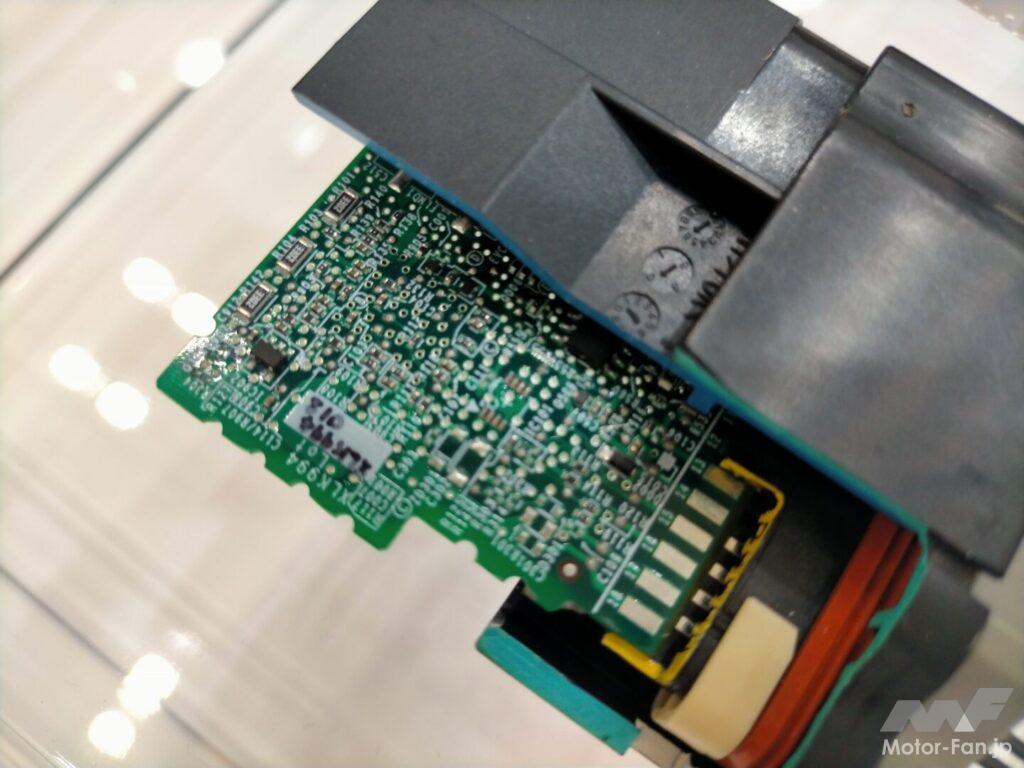

ECU (Engine Control Unit) for air-cooled 4-stroke single-cylinder 125cc engine

The ECU (Engine Control Unit) collects information from various sensors and instructs the throttle body to create the ideal air-fuel mixture.

This EUC uses a card edge connector to achieve a compact design. It can accommodate various optional functions, such as map changes. Of the 34 pins, 11 are compatible with options. A fall sensor is built into the ECU.

Variable valve timing for large European motorcycles

This is the world’s smallest and lightest item, with ultimate miniaturization that allows for optimal valve timing adjustment. It improves engine output and torque, as well as fuel economy and exhaust gas performance.

Based on precision aluminum processing technology, we have achieved the limits of strength and size. This OCV is resistant to high vibrations (the only one in the world). It also uses a harness connector to withstand the high vibration environment unique to motorcycle engines.

●Specifications (VVT)

・Operating oil temperature range: -30 to -150°C

・Size (outer diameter x height): φ58 x 24.5 mm

*From camshaft end face to outermost VVT

・Theoretical torque: 3.2 Nm @ 200 kPa

・Weight: 170 g (excluding sprocket)

●Specifications (OCV)

・Operating oil temperature range: -30 to -130°C

・Performance: @90kPa

・Retard (0.1A) Maximum flow rate: 3.9L/min ・

Advance (1.0A) Maximum flow rate: 4.2L/min